Substrate Material:

- Glass: Corning Eagle XG, Eagle 2000, Borofloat, Standard float (soda-lime)

- Tempered Glass: Chemical or Heat Tempered

- Plastics: (Optional) Acrylic, Polycarbonate, others (consult with factory on issues)

Dimensions:

- Sizes: 14″ x 18″ (356mm x 457mm); 24″ x 24″ (610mm x 610mm); (variations considered, consult with factory)

- Tolerances for sizing: ±0.08″ (±2mm)

- Thicknesses: 0.010″ (0.25mm) to 0.50″ (12.7mm)

Process:

- ION BEAM SPUTTERING (Proven Superior Process) Over E-Beam

| Standard BBAR | UV BBAR | BBAR (C-Band) NIR | |

|---|---|---|---|

| Band | 420-670nm | 375-630nm | 1250-1600nm |

| Reflectance | 0.25% avg. | 0.25% avg. | 0.50% avg. |

| Transmission | ≥99.5% | ≥99.5% | ≥98%, coated 2 sides |

| Absorption (coating) | <0.1% | <0.1% | --- |

Coating Uniformity:

- ±2.5% across full sheet

Surface Quality:

- Defects ≤5 micron on large substrate

- Imbedded Particle ≤2 micron

- Surface Roughness ≤20Å RMS

- Inspection 5K Lux (for 20/10), 10K Lux (for 5/2)

Durability:

- Abrasion 200 strokes @ 2.5lb (MIL C-675)

- Adhesion Snap Test (MIL M-13508)

- Solubility > 24 hours in NaCl, Fog and Solution (MIL C-675)

- Temperature > 12 hours @ -55° to 350°C

Packaging:

CLASS 100 Or As Customer Requirements

The TFD “superior” process advantage:

- TFD offers Ion Beam Sputtering versus others E-Beam processes.

- Extremely low surface roughness ≤ 20 Angstroms (rms) compared to E-Beam.

- Extremely low imbedded particle defects of ≤ 5µm.

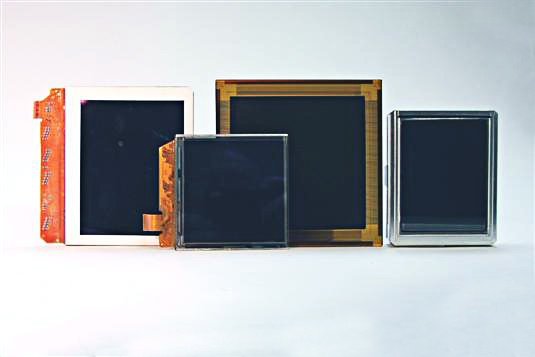

- Excellent process to support LCoS, DPL, micro mirrors, Oled, TFT displays, heaters, EMI shields and C band IR shutters.

- All coatings withstand up to 450 °C and severe reliability tests.